Hot-Dip Galvanized Cable Tray Price

Hot dip galvanizing, also known as hot-dip galvanizing, is an effective method of metal corrosion prevention and has been widely used on metal materials in various industries. Hot dip galvanizing is the process of immersing the rust removed bridge into a molten zinc solution at a high temperature of 600 ℃ to attach a zinc layer to the surface of the bridge. The thickness of the zinc layer should not be less than 65 μ m for thin plates below 5 mm and 86 μ m for thick plates, in order to achieve anti-corrosion.

The phenomenon of solvent inclusions or exposed iron on the surface of the zinc layer is mainly caused by incomplete degreasing of the component before galvanizing, insufficient acid washing, or solvent sticking after treatment. The corrosive effect of solvents on the galvanized layer must be eliminated. Exposed iron is also caused by not being immersed in galvanizing solution. Poor degreasing by acid washing and uneven material, as well as pits and indentations, can cause iron exposure.

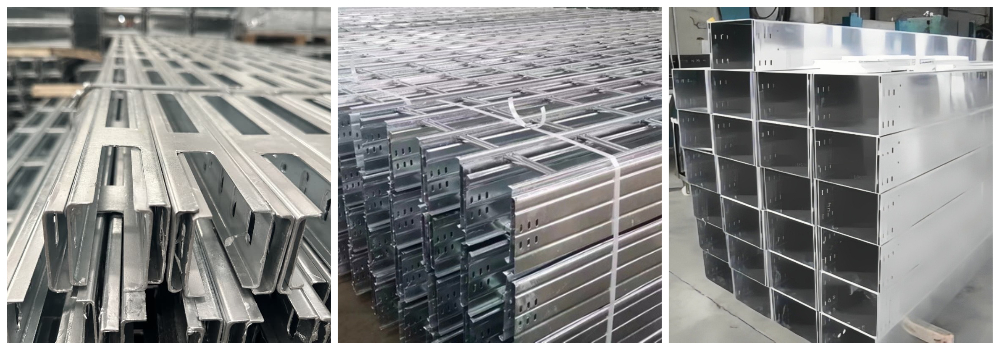

Introduction of the product:

When selecting a suitable hot-dip galvanized cable tray, the following key factors should be considered:

1. Environmental factors: Choose a suitable hot-dip galvanized bridge according to the degree of corrosiveness of the usage environment to ensure that its anti-corrosion performance meets actual needs.

2. Load bearing requirements: Select hot-dip galvanized cable trays with sufficient strength and rigidity, and appropriate specifications based on the number, weight, and wiring requirements of the cables.

3. Material and process: Ensure that the bridge material is hot-dip galvanized to ensure good corrosion resistance and a longer service life. Meanwhile, pay attention to the thickness of the zinc layer to meet the anti-corrosion requirements.

4. Structure and accessories: Choose a bridge with a reasonable structure and easy assembly, and ensure that accessories such as connecting plates and fasteners match the quality and accuracy of the bridge itself.

5. Maintenance and upkeep: Although hot-dip galvanized cable trays have excellent anti-corrosion performance, regular maintenance and inspection are still necessary to extend their service life.

Production process:

Application:

Hot dip galvanized cable trays have been extensively used in quite a number fields such as power, petrochemicals, metallurgy, transportation, and conversation due to their terrific overall performance and broad applicability. Whether in indoor or outside environments, whether or not in dry or humid conditions, hot-dip galvanized cable trays can exhibit true working prerequisites and secure performance. Its numerous specs and bendy set up strategies additionally meet the customized desires of exclusive engineering projects.

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd. is a superb employer fabric employer devoted to the cable tray engineering industrial corporation commercial enterprise company for a prolonged time. It adopts internationally most environment first-rate cable tray manufacturing science and has a domestically predominant cable tray one-time molding manufacturing line.

Our quintessential merchandise consist of galvanized cable trays, stainless metal cable trays, aluminum alloy cable trays, fire-resistant cable trays, and polymer cable trays. Our manufacturing unit has sturdy technical strength, with expert product designers and administration personnel. In the design and manufacturing of cable trays, we have in addition absorbed ordinary utilized sciences and experiences at home and abroad, and have instructing from professional authorities who have participated in cable tray plan and manufacturing for many years. The elements of the cable tray have been serialized and standardized. The novel form, clever structure, complete specifications, and flexible configuration have created pinnacle notch stipulations for shortening the placing up dimension of the project.

Production workshop: