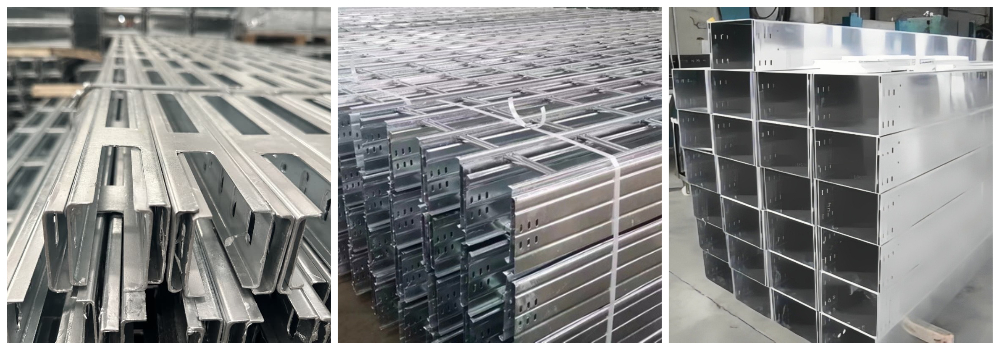

Hot Dipped Galvanized Cable Tray

Hot dip galvanizing, additionally acknowledged as hot-dip galvanizing, is an nice technique of metallic corrosion prevention and has been extensively used on metallic substances in more than a few industries.

Hot dip galvanizing is the technique of immersing the rust eliminated bridge into a molten zinc answer at a excessive temperature of 600 ℃ to connect a zinc layer to the floor of the bridge. The thickness of the zinc layer need to now not be much less than sixty five μ m for skinny plates beneath 5 mm and 86 μ m for thick plates, in order to acquire anti-corrosion.

The phenomenon of solvent inclusions or uncovered iron on the surface of the zinc layer is typically precipitated by using incomplete degreasing of the thing earlier than galvanizing, inadequate acid washing, or solvent sticking after treatment. The corrosive impact of solvents on the galvanized layer should be eliminated. Exposed iron is additionally prompted by using no longer being immersed in galvanizing solution. Poor degreasing via acid washing and uneven material, as nicely as pits and indentations, can purpose iron exposure.

Introduction of the product:

When choosing a appropriate hot-dip galvanized cable tray, the following key elements have to be considered:

1. Environmental factors: Choose a appropriate hot-dip galvanized bridge in accordance to the diploma of corrosiveness of the utilization surroundings to make certain that its anti-corrosion overall performance meets proper needs.

2. Load bearing requirements: Select hot-dip galvanized cable trays with ample electricity and rigidity, and fabulous specs based totally on the number, weight, and wiring necessities of the cables.

3. Material and process: Ensure that the bridge cloth is hot-dip galvanized to make certain correct corrosion resistance and a longer provider life. Meanwhile, pay interest to the thickness of the zinc layer to meet the anti-corrosion requirements.

4. Structure and accessories: Choose a bridge with a life like shape and effortless assembly, and make sure that add-ons such as connecting plates and fasteners fit the first-rate and accuracy of the bridge itself.

5. Maintenance and upkeep: Although hot-dip galvanized cable trays have first-rate anti-corrosion performance, ordinary protection and inspection are nonetheless indispensable to prolong their carrier life.

Production process:

Application:

Hot dip galvanized cable trays have been drastically used in pretty a wide variety fields such as power, petrochemicals, metallurgy, transportation, and dialog due to their extremely good typical overall performance and wide applicability. Whether in indoor or backyard environments, whether or not or no longer in dry or humid conditions, hot-dip galvanized cable trays can showcase real working stipulations and impenetrable performance. Its severa specs and flexible set up techniques moreover meet the personalized needs of distinct engineering projects.

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd. is a extraordinary business enterprise material agency dedicated to the cable tray engineering industrial organisation industrial agency agency for a extended time. It adopts internationally most surroundings terrific cable tray manufacturing science and has a domestically predominant cable tray one-time molding manufacturing line.

Our quintessential merchandise consist of galvanized cable trays, stainless metallic cable trays, aluminum alloy cable trays, fire-resistant cable trays, and polymer cable trays. Our manufacturing unit has sturdy technical strength, with specialist product designers and administration personnel. In the plan and manufacturing of cable trays, we have in addition absorbed regular utilized sciences and experiences at domestic and abroad, and have instructing from expert authorities who have participated in cable tray sketch and manufacturing for many years. The factors of the cable tray have been serialized and standardized. The novel form, sensible structure, entire specifications, and bendy configuration have created pinnacle notch stipulations for shortening the setting up dimension of the project.

Production workshop: