Ensure the safety of fireproof trough cable tray during maintenance

The installers of fireproof trough cable trays should have the corresponding electrical installation qualifications, undergo safety training, and understand the relevant safety regulations and operating procedures. During the installation process, the safety operating procedures should be strictly followed to ensure the personal safety of the staff and the safety of the equipment.

Cable load control is an important factor in ensuring the safety of fireproof trough cable trays. When installing the cable tray, the cable load should be reasonably arranged according to factors such as the cable cross-sectional area, length, and bending radius to avoid overloading or underloading. At the same time, the cable load should be checked regularly to ensure the safe operation of the cable.

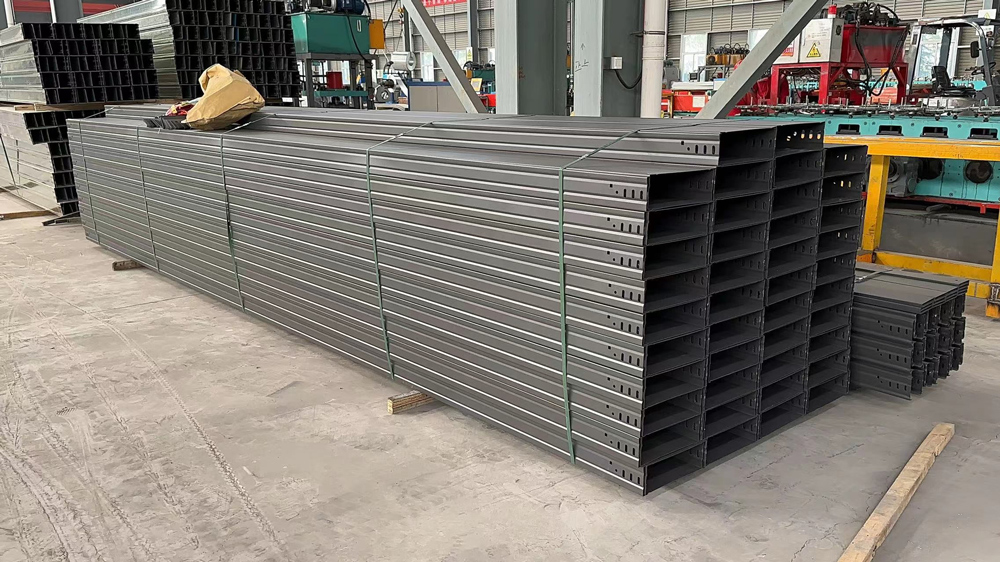

The selection of fireproof materials is an important part of the fireproof trough cable tray. When selecting the cable tray material, cold-rolled steel plates should be selected and special anti-corrosion treatments such as spraying or galvanizing should be performed. At the same time, in order to meet the fire protection requirements, the filling materials inside the cable tray should be non-combustible materials to prevent the spread of flames and smoke.

When installing the fireproof trough cable tray, grounding protection should be carried out. Grounding protection can effectively reduce the impact of leakage and static electricity on equipment and personnel, and improve the safety and stability of equipment. At the same time, grounding protection is also an important requirement in electrical safety specifications. During the maintenance of fireproof trough cable trays, corresponding safety regulations should be followed, and protective gloves, helmets and other protective equipment should be worn to avoid accidental injuries during operation. At the same time, for some high-altitude operations or special environment operations, relevant safety specifications and technical requirements should be followed to ensure the safety and stability of the operation.

Regular inspection and maintenance are important measures to ensure the safety of fireproof trough cable trays. Regularly check whether the fixing screws and locks of the perforated cable trays are tightened, whether the brackets and cable trays are loose or deformed, and whether the cable lines are damaged or aged. Problems should be dealt with in a timely manner to avoid safety accidents. At the same time, the filling materials inside the cable tray should be inspected and replaced to ensure the reliability of fireproof performance.

The installation method of the trough cable tray supplier can be flexibly adjusted and selected according to different environmental conditions to meet the needs of various scenarios. The following introduces several common installation methods and the environmental conditions they adapt to:

1. Indoor environment: For indoor environments, trough cable tray suppliers can use ground installation or ceiling installation. Floor installation requires the cable tray to be installed on the ground or floor slab, which is usually suitable for places with relatively low indoor clearance and large space. Ceiling installation is suitable for places with limited height or where the cable tray needs to be hidden, such as offices, shopping malls, etc.

2. Outdoor environment: For outdoor environment, trough cable tray suppliers can use direct burial installation or support installation. Direct burial installation is suitable for places with high landscape requirements, such as parks, squares, etc. The cable tray can be buried underground and installed without affecting the ground landscape. Bracket installation is suitable for places such as cable trays and roads. Through bracket installation, the cable tray can be fixed on the building or bracket to protect the cable from damage.

3. High humidity environment: For high humidity environment, such as toilets and bathrooms, spray trough cable tray can be installed in a closed or waterproof manner. Closed installation is to seal the cable tray in a closed box to prevent water vapor and dust from entering. Waterproof installation requires that the cable tray itself has a certain waterproof performance and can withstand a certain degree of immersion and moisture.

4. Corrosive environment: For corrosive environments, such as chemical, marine and other places, spray trough cable tray suppliers can use anti-corrosion or acid-alkali resistant installation. Anti-corrosion installation requires special anti-corrosion treatment on the surface of the cable tray to enhance its corrosion resistance. Acid-alkali resistant installation requires the cable tray