Customized Molded Cable Tray

The manufacturing process of molded cable trays mainly includes the following key steps:

1. Mold design and manufacturing: Design molds based on the specifications, dimensions, and structural requirements of the bridge. Molds are usually made of steel or cast iron and require precision machining.

2. Material preparation: Select suitable materials such as cold-rolled steel, hot-dip galvanized steel, or aluminum alloy, and cut them.

3. Compression molding: Place the heated material into a mold and press it into the desired bridge shape through the pressure of the mold.

4. Cooling and trimming: The molded bridge is cooled in the mold and then trimmed, such as removing burrs.

5. Surface treatment: Perform rust removal treatment and perform surface treatments such as hot-dip galvanizing and spraying according to requirements.

6. Quality inspection: Conduct size, strength, and appearance checks on the bridge frame to ensure product quality.

7. Packaging and Shipping: Packaging qualified cable trays and shipping them to the customer's designated location.

Introduction of the product:

There are various specifications for molded cable trays, mainly including the following:

1. Structural types: including tray type (P), trough type (C), ladder type (T) and other types to meet different cable laying needs.

2. Size specifications: Common specifications include 100100, 10040, 12050, etc., as well as larger sizes such as 200mm × 80mm, 200mm × 100mm, 300mm × 100mm, etc. In addition, there are some special or large specifications such as 250125, 250 * 150, 800mm × 300mm, 1200mm × 200mm, etc., which meet the cable laying requirements of different places. The specifications and dimensions can be customized according to specific needs.

3. Wall thickness: The commonly used wall thickness for cable trays ranges from 0.8mm to 2.5mm, and the specific thickness depends on the material and load-bearing requirements.

In summary, the specifications of molded cable trays are diverse and can be selected and customized according to actual application scenarios and needs to meet the cable laying requirements of different projects.

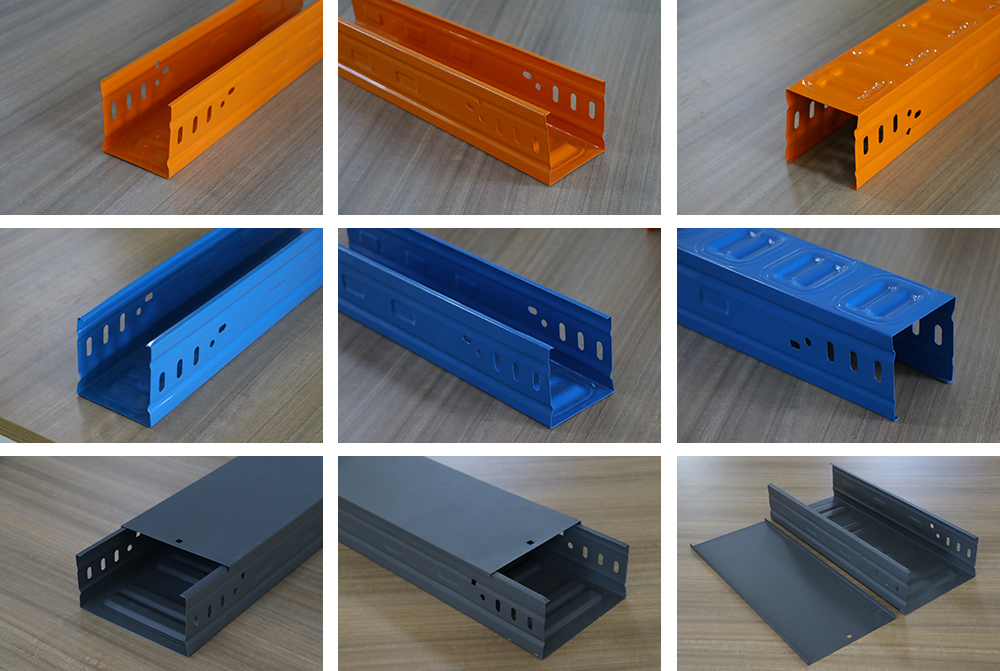

Product display:

Production process:

Application:

With the continuous development of materials science, molded cable trays will be made of higher performance materials to improve their load-bearing capacity, corrosion resistance, and fire resistance. With the continuous development of Internet of Things technology, molded cable trays will achieve intelligent management. Through sensors and data analysis technology, the real-time monitoring of cable operation status will improve the efficiency and safety of cable management.

As a new type of cable tray product, molded cable tray is gradually becoming a new choice for cable management due to its unique advantages and wide range of applications. With the continuous advancement of technology and the continuous development of the market, the application prospects of molded cable trays will be even broader.

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd., notably primarily based in Liaocheng City, Shandong Province—known as the "Water City of Jiangbei" and the "Canal City" for its picturesque environment and on hand transportation—specializes in the cable tray engineering industry. As a professional producer committed to the research, development, production, sales, and set up of cable trays, the corporation affords remarkable components and services. Utilizing internationally most advantageous manufacturing tactics and geared up with a primary domestic one-time forming manufacturing line for cable trays, Shandong Bolt ensures ultimate best and effectivity in its offerings. The business enterprise is a professional producer specializing in the search for and development, production, earnings and set up of cable tray, adopting the world most advantageous cable tray manufacturing process, with the contemporary domestic primary stage of the tray as quickly as formed manufacturing line. At present, the manufacturing unit covers an neighborhood of 20,000 rectangular meters, with larger than 230 employees, the frequent every day output of about one hundred twenty tons, with a range of built-in manufacturing traces and many computerized equipment. Our manufacturing facility pursues the agency philosophy of “quality as the basis, integrity as a guarantee, administration to be effective, innovation and development”, adheres to the industrial employer philosophy of “customer-centered”, continuously seeks for perfection, besides a doubt returns to the society, and builds a remarkable future for the blue water and the blue sky with awesome merchandise and perfect service.

Production workshop: