Molded Reinforced Cable Tray

1. Energy Saving: Concave-convex format cuts fabric and electricity use, saving over 40% in contrast to normal cable tray.

2. Light & Strong: 70%-85% of usual cable tray thickness, lighter with superior load capacity, eco-friendly and cost-effective.

3. Corrosion Resistant: Made from corrosion-resistant materials, making sure sturdiness in harsh environments.

4. Aesthetic Design: Streamlined, three-d appearance, current and distinctive.

5. Customizable: Available in quite a number lengths to meet precise needs.

6. Enhanced Stiffness: Molding will increase axial second of inertia, boosting flexural stiffness and strength.

Introduction of the product:

Molded cable tray is a form of energy-saving cable tray, which no longer solely reduces the weight of the cable tray, however additionally improves its power and load ability via a different molding process, and at the equal time has properly corrosion resistance and stunning structure. The core benefits of molded cable tray mostly encompass strength saving, mild weight and excessive strength, corrosion resistance and stunning structure. The energy-saving of molded cable tray is proven in its uneven shape design, which no longer solely saves substances however additionally saves electricity, saving extra than 40% of substances than usual cable tray. In addition, the thickness of molded cable tray is solely 70%~85% of the standard cable tray, the usage of less cloth and weighing less, however the load capability is enhanced, this sketch is each environmentally pleasant and economical. In phrases of power and corrosion resistance, molded cable tray acquire improved bending stiffness thru the backside molding and special design, which will increase the axial second of inertia significantly. This kind of cable trayis made of quite corrosion-resistant materials, such as shade metal natural coating and VCI bimetallic inorganic coating, to make certain its sturdiness in notably corrosive environments. Molded cable tray additionally have stunning buildings and various customization services. Its high-tech manufacturing technique and third-dimensional streamlined layout provide the product a different 3-dimensional sense. In addition, molded cable tray can be made in distinctive lengths to meet extraordinary needs.

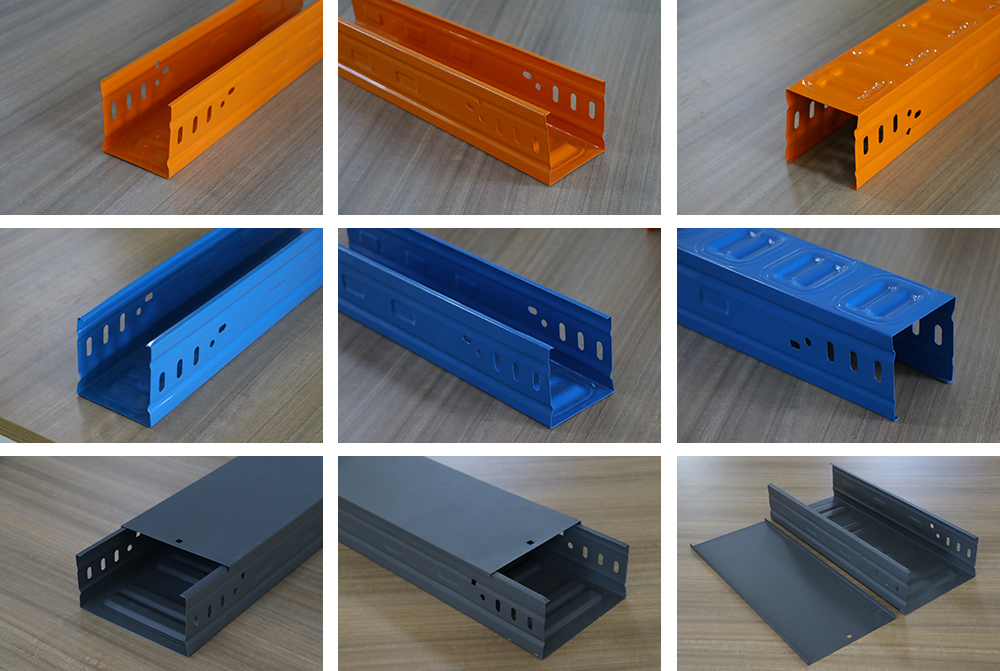

Product display:

Production process:

Application:

Cable tray is broadly used in a number scenarios, particularly in buildings, amenities or gear that require a lot of cable wiring. Its major function is to lift and defend cables to make sure protected operation and high quality administration of cables.

In the manufacturing services of electric powered power, chemical industry, metallurgy and different industries, cable tray is used to control and shield electricity transmission, signaling and manipulate cables.

In energy plants, metal mills, oil refineries and different places, cable tray can make certain the secure laying of cable structures and keep away from cables being affected with the aid of exterior factors, such as furnace and mechanical damage.

Company Profile:

Shandong Bolt Electrical Equipment Co., Ltd., based totally in Liaocheng City, Shandong Province—known as the "Water City of Jiangbei" and the "Canal City" for its picturesque surroundings and handy transportation—specializes in the cable tray engineering industry. As a expert producer devoted to the research, development, production, sales, and set up of cable trays, the agency gives tremendous substances and services. Utilizing internationally superior manufacturing tactics and geared up with a main home one-time forming manufacturing line for cable trays, Shandong Bolt ensures most desirable great and effectivity in its offerings. The business enterprise is a expert producer specializing in the lookup and development, production, income and set up of cable tray, adopting the global superior cable tray manufacturing process, with the present day home main stage of the tray as soon as shaped manufacturing line. At present, the manufacturing unit covers an place of 20,000 rectangular meters, with greater than 230 employees, the common every day output of about one hundred twenty tons, with a variety of built-in manufacturing strains and many computerized equipment. Our manufacturing facility pursues the commercial enterprise philosophy of “quality as the basis, integrity as a guarantee, administration to be effective, innovation and development”, adheres to the commercial enterprise philosophy of “customer-centered”, continually seeks for perfection, absolutely returns to the society, and builds a gorgeous future for the blue water and the blue sky with brilliant merchandise and best service.

Production workshop: