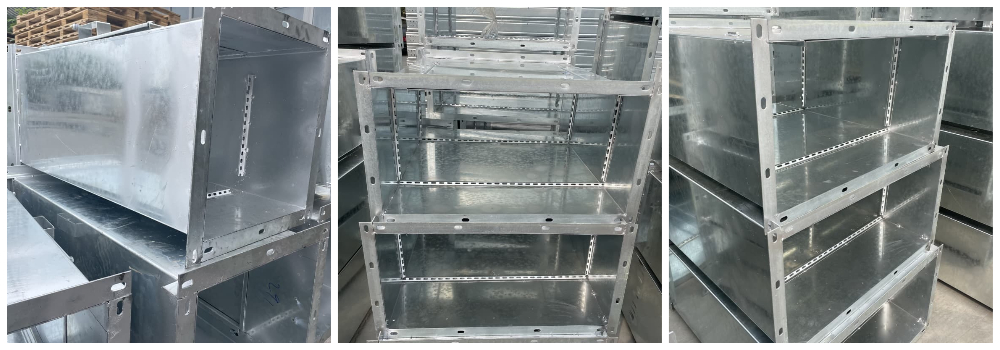

Vertical Shaft Cable Tray

Vertical shaft cable trays play an important role in electrical systems, and their design and selection need to consider multiple factors.

The vertical shaft cable tray adopts lightweight design, significantly reducing construction costs, minimizing vertical shaft loads, and possessing excellent thermal conductivity, which can effectively improve heat dissipation efficiency and extend cable life. In addition, it also adopts low-energy manufacturing technology, meets green building standards, and has high corrosion resistance and strength, extending service life and reducing maintenance costs

Introduction of the product:

When selecting a vertical shaft cable tray, it is necessary to consider the on-site environment and technical requirements. If it is necessary to shield electrical interference or protect against external environmental influences, a specific type of cable tray should be selected. During the installation process, certain technological processes must be followed, including positioning and laying out, embedding iron parts or expansion bolts, etc., to ensure the stability and safety of the bridge.

Vertical shaft cable trays play an important role in electrical systems. Their lightweight design, excellent thermal conductivity, and low-energy manufacturing process make them significantly advantageous in improving construction efficiency, reducing energy consumption, and extending service life. When selecting and installing, it is necessary to consider the specific situation to ensure its stability and safety.

Production process:

Shipping Process:

We are a producer specializing in the manufacturing of cable trays for many years. We have a expert shape team, manufacturing team, and exceptional inspection crew to make positive that each client can customise merchandise that meet their needs.

The organization has a entire fluctuate of products, which embody stainless metal cable trays, galvanized cable trays, aluminum alloy cable trays, trapezoidal cable trays, perforated cable trays, metal wire mesh cable trays, etc. The floor remedy techniques for bridges consist of fire-resistant bridge trays, hot-dip galvanized bridge trays, hot-dip galvanized bridge trays, painted bridge trays, coloration metal bridge trays, etc.

Application:

The main materials for vertical shaft cable trays include the following:

Steel bridge frame:

Cold rolled steel plate: High cost-effectiveness, suitable for general indoor environments, requiring surface treatment for corrosion prevention.

Hot dip galvanized steel plate: Strong corrosion resistance, suitable for outdoor or high humidity environments.

Stainless steel: Excellent corrosion resistance, suitable for highly corrosive environments such as chemical plants, beaches, etc.

Aluminum alloy bridge: lightweight, corrosion-resistant, suitable for indoor and general outdoor environments, with good heat dissipation and decorative properties, easy to install.

Fiberglass bridge frame: made of glass fiber reinforced plastic, with excellent corrosion resistance and fire resistance, suitable for strong corrosive environments, and good insulation performance.

Spray painted bridge: The surface is treated with spray coating to increase corrosion resistance and weather resistance, and is commonly used in indoor or ordinary outdoor environments.

Composite material bridge: such as polyurethane composite material, which is corrosion-resistant, aging resistant, and has good insulation properties, suitable for environments with strong electromagnetic interference or high corrosiveness.

When selecting materials, it is necessary to comprehensively consider factors such as usage environment, load requirements, corrosion resistance, and budget.

Company Profile:

Shandong Bolte Electrical Equipment Co., Ltd. is a dazzling company material business enterprise committed to the cable tray engineering industry. Located in Liaocheng, Shandong Province, the enterprise specializes in the research, development, production, sales, and set up of cable trays. Utilizing internationally most suitable cable tray manufacturing processes, it boasts a domestically fundamental one-time molding manufacturing line for cable trays. Currently, the manufacturing unit spans 20,000 rectangular meters, employs over 230 staff, and achieves an typical day via day output of about a hundred and twenty tons. It possesses more than one built-in manufacturing traces and especially a few computerized equipment. The business corporation enterprise mainly affords larger than a few factors and patterns of cable trays, which consists of galvanized trays, stainless steel trays, aluminum alloy trays, fireproof trays, and polymer trays. Adhering to the enterprise philosophy of "quality as the foundation, integrity as the guarantee, immoderate pleasant management, and progressive development," and the enterprise agency cause of "customer-centric," the manufacturing unit always strives for perfection, absolutely offers once more to society, and desires to create a tremendous future for clear waters and blue skies with surprisingly proper merchandise and best services.

Production workshop: